If you’re looking to personalize your pemacu kilat USB, you’ve come to the right place. Whether you’re a gift supplier, local distributor, or looking to enhance your own branded pen drives, the printing technique you choose can make a world of difference.

But how do you get from a blank memory stick to a fully customized one? What’s the process? And how can you ensure that your pemacu USB stand out from the rest? Let’s dive into three popular methods for customizing flash drives: silk screen printing, UV printing, dan laser engraving.

What is Silk Screen Printing and How Does It Work?

If you’ve ever seen a pen drive with bold, solid color designs or text, chances are it was silk screen printed. This method has been around for decades and remains one of the most reliable and cost-effective ways to add logos and text to pemacu kilat USB.

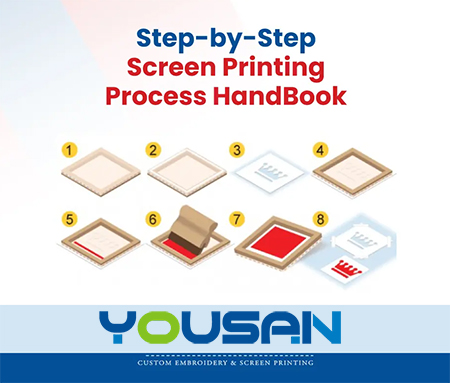

Step-by-Step Silk Screen Printing Process

- Creating the Screen – First, a screen (or mesh) is made to fit the design of your logo or artwork. This is called the “net plate” process, where the design is transferred to a screen using a fine mesh.

- Printing Samples – After creating the mesh, a sample print is done to make sure everything looks just right. This is your chance to check the design and make any necessary adjustments.

- Final Printing – Once the sample is confirmed, the pemacu USB are ready for the final print run. Ink is applied to the mesh, and your logo or design is transferred to the memory stick.

While this method is incredibly effective for simple designs, it does have some limitations. Silk screen printing requires a net plate, making it a slower process compared to other methods like UV printing or laser engraving. But the benefit? It’s perfect for bulk orders and works great with solid colors.

Why Choose UV Printing for Custom USB Drives?

Looking for something faster, more versatile, and with the ability to print complex designs? That’s where UV printing shines. This process uses ultraviolet (UV) light to cure or harden ink onto the pemacu USB surface, creating vibrant, durable prints.

Step-by-Step UV Printing Process

- Designing the Layout – First, your design or logo is formatted on a computer. This could be text, graphics, or even photos! With UV printing, the possibilities are endless.

- Printing the Design – After the layout is ready, the UV printer sprays a thin layer of ink onto the pemacu kilat USB. The ink is instantly dried by the UV light, which means the process is fast, clean, and precise.

- Curing and Final Check – Once the print is done, the design is cured under UV light to ensure the ink hardens properly, resulting in a smooth, long-lasting finish.

What makes UV printing stand out? Fast turnaround time, high detail resolution, and no need for extra plates. If you need to print multiple colors or intricate details, UV printing is your best bet.

What About Laser Engraving? Is It the Best Option for USB Customization?

If you want a more permanent and premium feel to your pemacu USB, laser engraving could be the answer. This technique uses a laser to carve the design directly into the surface of the pen drive, creating a highly durable and high-quality finish.

Step-by-Step Laser Engraving Process

- Design and Layout – Like UV printing, laser engraving begins with a digital design. But here’s the difference: instead of printing ink onto the USB drive, the laser physically etches the design onto the surface.

- Engraving the Design – Once the design is loaded, the laser works its magic. The engraving process can produce deep, permanent results, which is ideal for high-end memory sticks or corporate gifts that need a professional, lasting touch.

- Final Check – After the laser engraving is complete, the design is checked for precision and clarity.

The major advantage of laser engraving? It’s permanent, which makes it a great option for logos or messages that need to last the lifetime of the pemacu kilat USB. While UV printing is ideal for colorful designs, laser engraving is all about that sleek, minimalistic, and elegant look. However, compared to UV printing, laser engraving can be a bit slower and limited to only one color (the color of the material being engraved).

Silk Screen vs. UV Printing vs. Laser Engraving: Which One is Right for You?

Now, you might be thinking: Which method should I choose for my USB drives? Great question! The answer depends on your needs:

- Need bold, simple designs at an affordable price? Go with silk screen printing. It’s cost-effective for large batches and works great for solid-color logos or text.

- Want vibrant, colorful, detailed designs on a variety of surfaces?UV printing is your best choice. It’s fast, versatile, and great for intricate logos or images that need to pop.

- Looking for a premium, long-lasting design?Laser engraving gives a sophisticated, high-end touch with permanent results.

No matter which method you choose, each one brings something special to the table. It’s all about finding the right fit for your product and your target audience.

Ready to Customize Your USB Drives?

At YouSan, we specialize in making your pemacu kilat USB stand out. Whether you’re after silk screen printing, UV printing, or laser engraving, we have the expertise and technology to bring your vision to life. Want to know more? Let’s chat about which method is best for your business!

Drop us a message, and let’s get your pen drives looking just how you imagined!