Metal USB Flash Drive FAQ

Common capacities for metal USB drives range from 4GB to 1TB, with mainstream options concentrated between 32GB and 256GB. Different capacities cater to distinct usage scenarios:

I. Entry-Level Capacity (4GB–16GB)

Common specifications: 4GB, 8GB, 16GB

Suitable scenarios: Storing only small files such as simple documents (Word/Excel), drivers, small images (JPG format), and short audio clips (MP3).

Characteristics: Small capacity, low price (typically ¥20-50), but increasingly replaced by larger capacities. Suitable only for minimal needs (e.g., booting legacy devices, temporarily transferring small files).

II. Mainstream Capacity (32GB-256GB)

Common specifications: 32GB, 64GB, 128GB, 256GB

Use Cases: Meets most users’ daily needs, including

Daily Office Work: Storing large volumes of documents, PPTs, PDFs, and even small videos (e.g., meeting recordings);

Personal Use: Storing phone photos/videos (approx. 1000 HD photos = 10GB, 1 hour of short video = 5-8GB), car music (hundreds of songs = 5-10GB);

Light Creative Work: Storing design drafts (small PSD files), student assignments, etc.

Features: Offers the best value for money, typically priced between 50-200 RMB. This is the highest-selling capacity range in the market, compatible with the vast majority of computers, smartphones, and in-car devices.

Material Selection

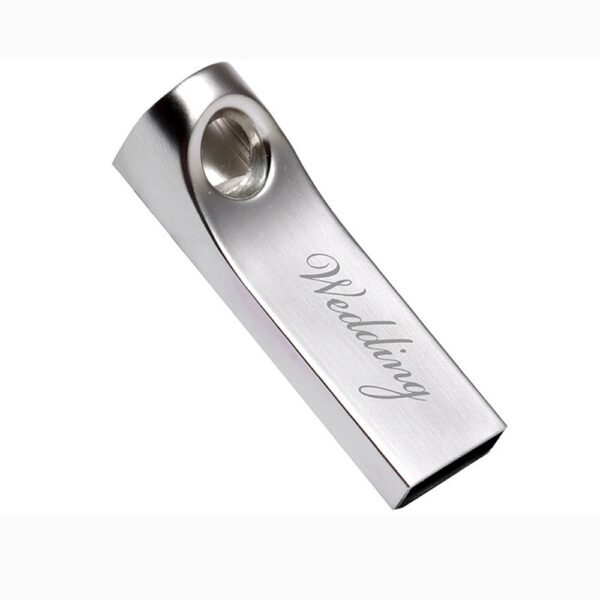

Aluminum Alloy: Lightweight and wear-resistant, suitable for laser engraving, commonly used in business gifts.

Stainless Steel: Highly corrosion-resistant with a substantial feel, but more challenging to process and higher in cost.

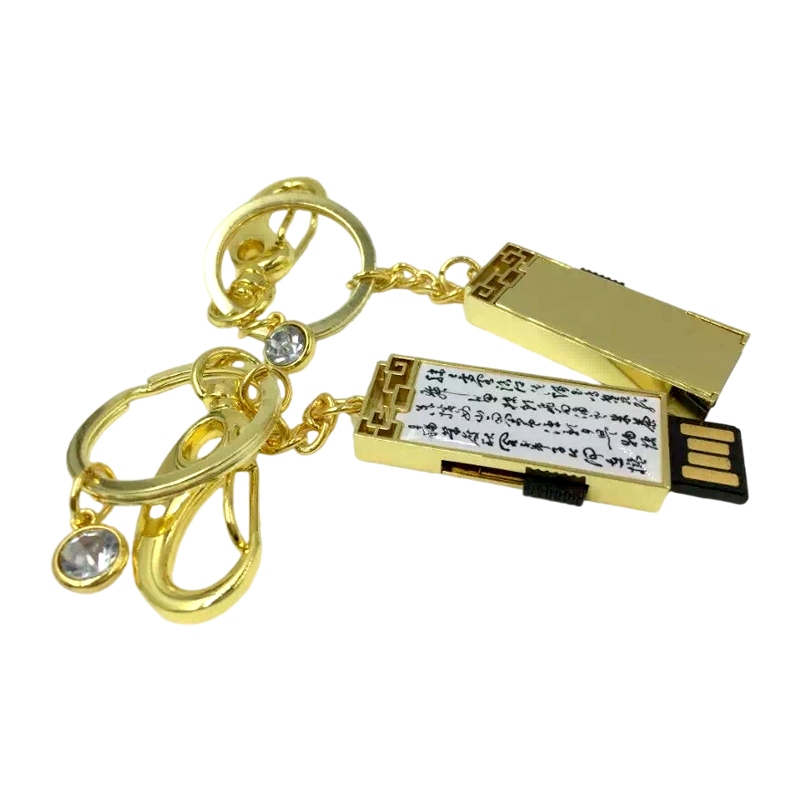

Zinc Alloy: Capable of die-casting intricate shapes (e.g., bullet heads, five-pointed stars), ideal for creative designs, though relatively heavy.

Laser Engraving: Permanently etches patterns onto metal surfaces with 20-year color retention, ideal for minimalist logos or text.

Screen Printing / Color Printing: Capable of multi-color designs, though color saturation and durability slightly inferior to laser engraving; suitable for simple color blocks.

Anodizing: Achieves colors beyond the metal’s natural hue (e.g., deep space gray, iridescent purple) through electrolytic coloring. Offers long-lasting color and scratch resistance.

Special Processes: Such as openwork engraving (Chinese-style screen designs) and enamel filling (vintage texture), which require mold development.