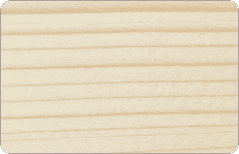

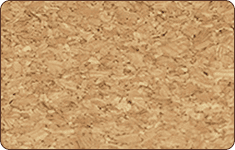

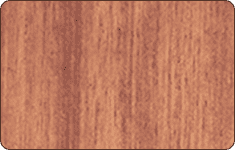

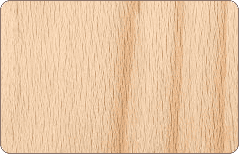

A: Natural wood’s grain and hue depend on its growing environment and the section from which it’s cut. Variations in shade and pattern are inevitable, even within one batch. We recommend requesting multiple samples in advance to confirm the overall look.

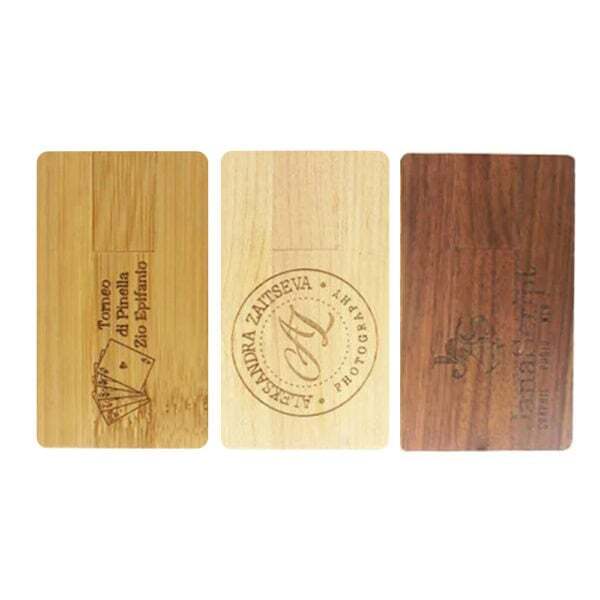

A: The main options are:

Laser engraving: ideal for simple line art, very durable

UV color printing: supports multicolor and gradients

Screen printing: best for large-area solid colors

Hot-stamping (gold/silver foil): for metallic sheen effects

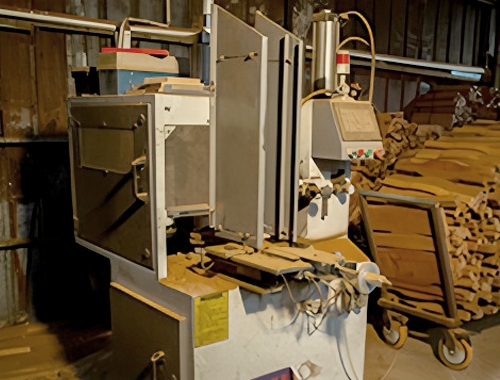

A: Use properly kiln-dried wood (moisture ≤8%), apply pore-sealing, coatings, or resin fill, and design adequate wall thickness. These measures effectively reduce the risk of cracking and deformation.

A: Consider recycled paper boxes, wooden gift boxes, or bamboo cases with velvet, foam, or flocked inserts. You can laser-engrave or foil-stamp your logo on the exterior and include a card or drawstring pouch to enhance the unboxing experience.

A: The typical MOQ is 100 pieces. Some factories can accept 50 pieces, but unit prices will be higher. If you need an even smaller batch, discuss sample fees and pricing with the manufacturer.

A: Laser samples can be ready in about 1 hour; color or specialty-process samples usually take 1–3 days. Bulk production generally requires 7–15 days, depending on quantity and process complexity.

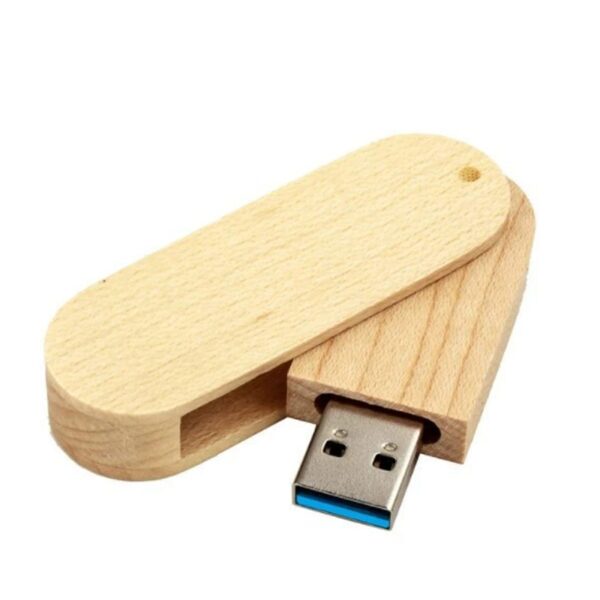

A: The wooden shell is purely aesthetic and does not impact the chip’s performance. To ensure stable speeds and compatibility, choose reputable chip brands (e.g., Original Amlogic, Hynix, etc.).

A: After use, gently wipe the surface with a soft, dry cloth. Avoid prolonged exposure to high heat or humidity. If the finish wears down, you can apply a thin coat of natural wood wax or oil for upkeep.

A: Source wood certified by FSC/PEFC and use coatings that comply with RoHS and REACH. If exporting, the factory can provide relevant test reports.